PICBASIC

PLUS LITE

COMPILER

Please

Note.

The LITE

version of the PICBASIC PLUS compiler offers an opportunity to write a program

for the PIC first hand. See for yourself how powerful and easy to use the compiler really is.

The LITE

version is limited to 20 lines of code, with only one commnand per line, as

opposed to multiple commands, and unlimited lines in the full version. Anmother

limitation is the type of PIC supported. The LITE version is compatable with

the ever-popular 16F84 and 16F877 devices, with crystal frequencies of 4MHz and

20MHz only. The full version is compatable with all the 14-bit core devices, and

6 crystal frequencies. Another limitation is the lack of any graphic LCD commands.

Other than that, the compiler is fully operational.

Although every precaution has been taken with the preparation of this manual to ensure that any projects, designs or programs enclosed, operate in a correct and safe manner. The author and publisher assume no responsibility for errors or omissions. Neither is any liability assumed for the failure of any project, design or program, or any damage caused to equipment that it may be connected to, or used in combination with.

Copyright Crownhill Associates. All right reserved. No part of this publication may be reproduced, stored in a retrieval system, or distributed in any form or by any means without the written permission of the publisher or author.

The Microchip logo and name are registered trademarks of Microchip Technologies Inc.

The EPICtm programmer is a trade name of microEngineering Labs inc.

PICBASIC PLUS is a trade name of Crownhill Associates.

Published and distributed by Crownhill Associates Ltd

Author Les Johnson.

First Edition August 2001.

Table of Contents.

3.10. Ports and Other Registers

5 - PICBASIC PLUS

Commands and Directives. 22

6 - Incorporating Assembler into a BASIC program.

Special instruction mnemonics.

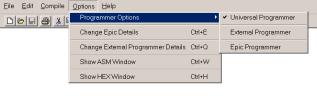

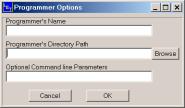

7.1. Using the on-board

Programmer

The PICBASIC PLUS compiler was written with simplicity and flexibility in mind. Using BASIC, which is almost certainly the easiest programming language around, you can now produce extremely powerful applications for your PIC without having to learn the relative complexity of assembler. Having said this, we have included various ‘enhancements’ for extra versatility and ease of use in the event that assembler is required.

PICBASIC PLUS provides a seamless development environment, found with no other PIC BASIC compiler, With PICBASIC PLUS , you can write, debug and compile your code within the same Windows environment, and by using a compatible programmer, just one key press allows you to program and verify the resulting code in the PIC of your choice!

It should be noted that PICBASIC PLUS is NOT code compatible with the popular Parallax PICBASIC, which is a proprietary language, specific to their BASIC Stamp Parts.

1.1. PIC Devices

The devices supported by this software are the most commonly used and the compiler takes advantage of their various features e.g. The A/D converter in the 16F87x series, the data memory eeprom area in the 16C84 and 16F84. This manual is not intended to give you details about PIC devices Therefore for further information, visit the Microchip website at www.microchip.com, and download the multitude of datasheets available.

Because of the limited architecture of the 12-bit devices, the compiler is only compatible with the 14-bit core types. This isn’t such a limitation, as the 16C55x range of devices may be used instead of the original 16C5x devices. If an 8-pin device is required, the incredibly flexible 12C67x range may be used.

1.2. PICBASIC PLUS Discussion

For your convenience we have set up a web site www.letbasic.com, where there is a section for users of PICBASIC to discuss the compiler, and provide self help with programs written for PICBASIC, or download sample programs. The web site is well worth a visit now and then either to learn a bit about how other peoples code works or to request help should you encounter any problems with programs that you have written.

To become a member of the discussion list, send an email to: -

majordomo@qunos.net

In the message body enter: -

subscribe LETBASIC-L

This will then reply with a message to verify your email address and ask you to reply. Once this is done, messages may be sent to: -

letbasic-l@qunos.net

1.4. Contact Details

Should you need to get in touch with us for any reason our details are as follows: -

Postal: Crownhill Associates Limited

32 Broad Street

Ely, Cambridgeshire

CB4 4AH

Telephone: UK: 01353 666709

Int: +44 1353 666709

Fax: UK: 01353 666710

Int: +44 1353 666710

Email: Sales@crownhill.co.uk

Web Site: http://www.crownhill.co.uk

http://www/letbasic.com

2.1. Installing the software

Using Windows explorer, change to your CD and locate the program called setup or setup.exe this is the main install application. Double‑click this and follow the on-screen prompts.

Note, the software is now fully installed on your hard drive so there is no need to put the CD in when you want to run it.

2.2. Ready to start ?

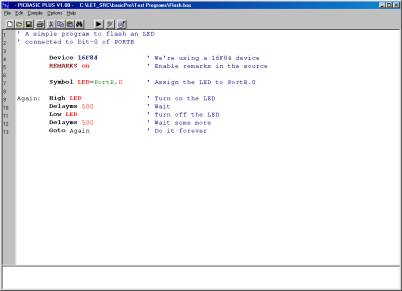

Once

the compiler is run you will be presented with an editor. This allows BASIC

code to be written, compiled, then programmed using one of many programmers.

The editor implements syntax highlighting for ease of use. All keywords,

numbers, comments etc have a different colour representing them.

|

|

|

|

The

editor window above, shows a simple program for flashing an LED.

The

program is compiled by clicking on the Compile button, ![]() or right clicking the mouse and choosing Compile. The program

will then be compiled and assembled, and if there are no errors in the code,

the Program button will be enabled. Any errors will be displayed on the

bottom window, along with the offending line or lines.

or right clicking the mouse and choosing Compile. The program

will then be compiled and assembled, and if there are no errors in the code,

the Program button will be enabled. Any errors will be displayed on the

bottom window, along with the offending line or lines.

As

an example of your first piece of code, enter the following program: -

DEVICE

16F84

DECLARE

XTAL 4

SYMBOL

LED = PORTB.0

Again: HIGH LED

DELAYMS 500

LOW LED

DELAYMS 500

GOTO Again

This

will flash an LED connected to bit-0 of PORTB.

Once

the compile button is pressed, the following text should be displayed in the

bottom window: -

PICBASIC COMPILED OK. 60 Words used from a possible 1024

26 Variables used in the

16F84 from a possible 68

The

text is pretty much self explanatory in that it informs you that 60 words are

used in the 16F84 device, which has 1024 (1K) of available program memory. The

same is true for the variables used. The word ‘variable’ is used to indicate

RAM memory, therefore if a WORD size variable is used in the program, it will

require two RAM locations. Even though the flashing LED program didn’t declare

any variables, the compiler always uses a minimum of 26 RAM locations, these

are it’s system variables.

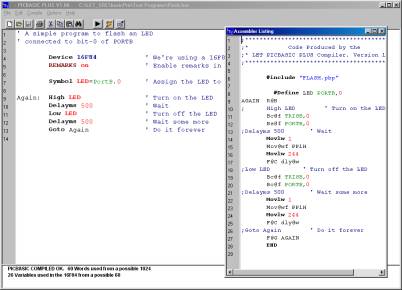

To

view the assembler code produced, click on the View button ![]() A new window will appear displaying the

assembled source code.

A new window will appear displaying the

assembled source code.

|

|

|

|

The code may now be

programmed into the PIC by clicking the program button ![]() ,

see section seven for details of the choices of programmer.

,

see section seven for details of the choices of programmer.

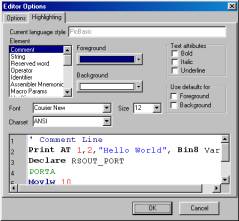

2.3. Customising the editor.

The editor itself may be

customised to a certain degree by choosing File->Editor Options. You

will be presented with an options box that allows the syntax colours to be

altered along with how the editor handles tabs etc: -

|

|

|

|

All

the new settings are remembered by the compiler, so there’s no need to alter them

every time the editor is opened.

As with any language,

there are rules you must follow when producing a program and PICBASIC PLUS is no exception. These are laid out in this

section.

3.1. Device specific issues.

Before venturing into

your latest project, always read the datasheet for the specific device being

used. Because some devices have features that may interfere with expected pin

operations. The PIC16C62x and the 16F62x devices are examples of this. These

PICmicros have analogue comparators on PORTA. When these chips first power up,

PORTA is set to analogue mode. This makes the pin functions on PORTA work in a

strange manner. To change the pins to digital, simply add the following line

near the front of your BASIC program, or before any of the pins are accessed: -

CMCON =

7

Any PICmicro with

analogue inputs, such as the PIC16C7xx, PIC16F87x and PIC12C67x series devices,

will power up in analogue mode. If you intend to use them as digital types you

must set the pins to digital by using the following line of code: -

ADCON1 =

7

Another example of

potential problems is that bit-4 of PORTA (PortA.4) exhibits unusual behaviour

when used as an output. This is because the pin has an open drain output rather

than the usual bipolar stage as in the rest of the output pins. This means it

can pull to ground when set to 0 (low), but it will simply float when set to a

1 (high), instead of going high.

To make this pin act as

expected, add a pull-up resistor between the pin and 5 Volts. A typical value

resistor may be between 1K and 33K, depending on the device it is driving. If

the pin is used as an input, it behaves the same as any other pin.

Some PICmicros, such as the PIC16F87x range, allow

low-voltage programming. This function takes over one of the PORTB (PortB.3)

pins and can cause the device to act erratically if this pin is not pulled low.

In normal use, It’s best to make sure that low-voltage programming is disabled

at the time the PICmicro is programmed. By default, the low voltage programming

fuse is disabled, however, if the CONFIG directive is used, then it may

inadvertently be omitted.

All of the PICmicro pins are set to inputs on

power-up. If you need a pin to be an output, set it to an output before you use

it, or use a BASIC command that does it for you. Once again, always read the

PICmicro data sheets to become familiar with the particular part.

The name of the port pins on the PIC12C67x and

12CE67x devices is GPIO. The name for the TRIS register is TRISIO: -

GPIO.0 = 1 ‘ Set GPIO.0 high

TRISIO = %101010 ‘ Manipulate ins and outs

3.2. Identifiers

An identifier is a

technical term for a name. Identifiers are used in PICBASIC PLUS for line labels, variable names, and

constant aliases. An identifier is any sequence of letters, digits, and

underscores, although it must not start with a digit. Identifiers are not case

sensitive, therefore label, LABEL, and Label are all treated as equivalent. And

while labels might be any number of characters in length, only the first 32 are

recognised.

3.3. Line Labels

In order to mark

statements that the program may wish to reference with the GOTO, CALL,

or GOSUB commands, PICBASIC PLUS

uses line labels. Unlike many older BASICs, PICBASIC PLUS doesn't allow or require line numbers and

doesn't require that each line be labelled. Instead, any line may start with a

line label, which is simply an identifier followed by a colon ‘:’.

Lab:

PRINT “Hello World”

GOTO

Lab

3.4. Variables

Variables are where

temporary data is stored in a BASIC program. They are created using the DIM

keyword. Because RAM space on PICmicros is somewhat limited in size, choosing

the right size variable for a specific task is important. Variables may be

bits, bytes or words. Space for each variable is automatically allocated in the

micro controller’s RAM area. The format for creating a variable is as follows:

-

DIM

Label as Size

Label is

any identifier, (excluding keywords). Size is BIT, BYTE or

WORD. Some examples of creating variables are: -

DIM

Dog as BYTE ‘ Create an 8-bit variable (0-255)

DIM

Cat as BIT ‘ Create a single bit variable (0-1)

DIM

Rat as WORD ‘ Create a 16-bit variable (0-65535)

The number of variables

available depends on the amount of RAM on a particular device and the size of

the variables within the BASIC program. PICBASIC PLUS reserves approximately 26 RAM locations for its own use. It may

also create additional temporary variables for use when calculating complex

equations.

There

are certain reserved words that cannot be used as variable names, these are the

system variables used by the compiler.

The

following reserved words cannot be used as variable names: -

PP0, PP0H, PP1, PP1H, PP2, PP2H, PP3, PP3H, PP4, PP4H, PP5, PP5H,

PP6, PP6H, PP7, PP7H, GEN, GENH, GEN2, GEN2H, GEN4, GEN4H, GPR, BPF.

3.5. Aliases

DIM

can also be used to create an alias to a variable. This is very useful for

accessing the separate parts of a variable.

DIM

Fido as Dog ‘ Fido is another name for Dog

DIM

Mouse as Rat.LOWBYTE ‘ Mouse is the first byte (low byte) of word Rat

DIM

Tail as Rat.HIGHBYTE ‘ Tail

is the second byte (high byte) of word Rat

DIM

Flea as Dog.0 ‘ Flea is bit-0 of Dog

3.6. Constants

Named constants may be created in the same manner

as variables. It can be more informative to use a constant name instead of a constant

number. Once a constant is declared, it cannot be changed later, hence the name

‘constant’.

DIM Label as Constant

expression

DIM Mouse as 1

DIM Mice as Mouse * 400

3.7. Symbols

SYMBOL provides yet another

method for aliasing variables and constants. SYMBOL cannot be used to

create a variable. Constants declared using SYMBOL do not use any RAM

within the PIC.

SYMBOL Tiger = cat ‘ Cat was previously created using DIM

SYMBOL Mouse = 1 ‘ Same as DIM Mouse as 1

SYMBOL

Tigouse = Tiger + Mouse ‘ Add Tiger to Mouse to make Tigouse

If

a variable or register’s name is used in a constant expression then the

variable’s or register’s address will be substituted, not the value held in the

variable or register: -

SYMBOL

CON = (PORTA + 1) ‘ CON will

hold the value 6 (5+1)

SYMBOL

is also useful for aliasing Ports and Registers: -

SYMBOL LED = PORTA.1 ‘ LED now references bit-1 of PortA

SYMBOL T0IF = INTCON.2 ‘ T0IF now references bit-2 of INTCON register

The

equal sign between the Constant’s name and the alias value is optional: -

SYMBOL LED PORTA.1 ‘ Same as SYMBOL LED=PORTA.1

3.8. Numeric Representations

PICBASIC

PLUS recognises four different number

representations: -

Binary

is prefixed by %. i.e. %0101

Hexadecimal

is prefixed by $. i.e. $0A

Character

byte is surrounded by quotes. i.e. “a” represents a value of 97

Decimal values need no prefix.

3.9. String Constants

PICBASIC PLUS

doesn't provide conventional string handling capabilities, but strings

can be used with some commands. A string contains one or more characters and is

delimited by double quotes.

PRINT "Hello

World" ‘ Output String

("H","e","l","l","o",”

“,"W","o","r","l","d")

Strings are usually treated as a list of individual

character values, and are used by commands such as PRINT, RSOUT, BUSOUT,

EWRITE etc.

3.10. Ports and Other Registers

All of the PICmicro registers, including the ports,

can be accessed just like any other byte-sized variable. This means that they

can be read from, written to or used in equations directly:

PORTA = %01010101 ‘ Write value to PORTA

Var = Wrd * PORTA ‘ Multiply variable WRD with the contents of PORTA

3.11. General Format

The

compiler is not case sensitive, except when processing string constants such as

“hello”.

Multiple

instructions and labels can be combined on the same line by separating them

with colons ‘:’.

The

examples below show the same program as separate lines and as a single-line...

Multiple-line

version: -

TRISB = %00000000 ' Make all pins on PortB outputs

FOR

Var = 0 TO 100

' Count from 0 to 100

PORTB = Var ' Make PortB = count (Var)

NEXT ' Continue counting until 100 is reached

Single-line

version: -

TRISB = %00000000 :

FOR Var = 0 TO 100 : PORTB =

Var : NEXT

-----------------------------------------------------------------------------------------------------------------

The PICBASIC PLUS

Compiler performs all math operations in full hierarchal order. Which

means that there is precedence to the operators. For example, multiplies and

divides are performed before adds and subtracts. To ensure the operations are

carried out in the correct order use parenthesis to group the operations: -

A

= (( B – C ) * ( D + E )) / F

All

math operations are unsigned and performed with 16-bit precision.

The

operators supported are: -

+ Addition

- Subtraction

* Multiplication

**

Top

16 Bits of Multiplication

*/

Middle

16 Bits of Multiplication

/ Division

//

Remainder

(Modulus)

<<

Shift

Left

>>

Shift

Right

&

Bitwise

AND

| Bitwise OR

^ Bitwise XOR

4.1.

Addition ‘+’.

The

Addition operator (+) adds variables and/or constants, returning a 16-bit

result. Works exactly as you would expect with unsigned integers from 0 to

65535. If the result of addition is larger than 65535, the carry bit will be

lost.

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = 1575

Value2 = 976

Value1 = Value1 + Value2 ' Add the numbers.

PRINT @Value1 ' Display the result

4.2.

Subtraction ‘-‘.

The

Subtraction operator (-) subtracts variables and/or constants, returning a

16-bit result. Works exactly as you would expect with unsigned integers from 0

to 65535.

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = 1000

Value2 = 999

Value1 = Value1 - Value2 ' Subtract the numbers.

PRINT @Value1 ' Display the result

4.3.

Multiply ‘*’.

The

Multiply operator (*) multiplies variables and/or constants, returning the low

16 bits of the result. Works exactly as you would expect with unsigned integers

from 0 to 65535. If the result of multiplication is larger than 65535, the

excess bits will be lost.

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = 1000

Value2 = 19

Value1 = Value1 * Value2 ' Multiply Value1 by Value2.

PRINT @Value1 ' Display the result

4.4.

Multiply HIGH ‘**’.

The

Multiply High operator (**) multiplies variables and/or constants, returning

the high 16 bits of the result. When multiplying two 16-bit values, the result

can be as large as 32 bits. Since the largest variable supported by the

compiler is 16-bits, the highest 16 bits of a 32-bit multiplication result are

normally lost. The ** (double-star) operand produces these upper 16 bits.

For example, suppose 65000 ($FDE8) is

multiplied by itself. The result is 4,225,000,000 or $FBD46240. The * (star, or

normal multiplication) instruction would return the lower 16 bits, $6240. The

** instruction returns $FBD4.

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = $FDE8

Value2 = Value1 ** Value1 ' Multiply $FDE8 by itself

PRINT hex Value2 ' Return high 16 bits.

4.5.

Multiply MIDDLE ‘*/’.

The

Multiply Middle operator (*/) multiplies variables and/or constants, returning

the middle 16 bits of the 32-bit result. This has the effect of multiplying a

value by a whole number and a fraction. The whole number is the upper byte of

the multiplier (0 to 255 whole units) and the fraction is the lower byte of the

multiplier (0 to 255 units of 1/256 each). The */ operand allows a workaround

for the compiler’s integer-only math.

Suppose

we are required to multiply a value by 1.5. The whole number, and therefore the

upper byte of the multiplier, would be 1, and the lower byte (fractional part)

would be 128, since 128/256 = 0.5. It may be clearer to express the */

multiplier in HEX as $0180, since hex keeps the contents of the upper and lower

bytes separate. Here's an example:

DIM Value1 as WORD

Value1 = 100

Value1 = Value1 */ $0180 ' Multiply by 1.5 [1 + (128/256)]

PRINT @Value1 ' Show result (150).

To

calculate constants for use with the */ instruction, put the whole number

portion in the upper byte, then use the following formula for the value of the

lower byte: -

INT(fraction

* 256)

For

example, take Pi (3.14159). The upper byte would be $03 (the whole number), and

the lower would be INT(0.14159 * 256) = 36 ($24). So the constant Pi for use

with */ would be $0324. This isn’t a perfect match for Pi, but the error is

only about 0.1%.

4.6.

Divide ‘/’.

The

Divide operator (/) divides variables and/or constants, returning a 16-bit

result. Works exactly as you would expect with unsigned integers from 0 to 65535.

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = 1000

Value2 = 5

Value1 = Value1 / Value2 ' Divide the numbers.

PRINT @Value1 ' Show the result (200).

4.7.

Modulus ‘//’.

The

Modulus operator (//) returns the remainder left after dividing one value by

another. Some division problems don’t have a whole-number result; they return a

whole number and a fraction. For example, 1000/6 = 166.667. Integer math

doesn’t allow the fractional portion of the result, so 1000/6 = 166. However,

166 is an approximate answer, because 166*6 = 996. The division operation left

a remainder of 4. The // returns the remainder of a given division operation.

Numbers that divide evenly, such as 1000/5, produce a remainder of 0: -

DIM Value1 as WORD

DIM Value2 as WORD

Value1 = 1000

Value2 = 6

Value1 = Value1 // Value2 ' Get remainder of Value1 / Value2.

PRINT @Value1 ' Show the result (4).

4.9. And ‘&’

The And operator (&) returns the bitwise

AND of two values. Each bit of the values is subject to the following logic: -

0 AND 0 = 0

0 AND 1 = 0

1 AND 0 = 0

1 AND 1 = 1

The

result returned by & will contain 1s in only those bit positions in which

both input values contain 1s: -

DIM Value1 as BYTE

DIM Value2 as BYTE

DIM Result as BYTE

Value1 = %00001111

Value2 = %10101101

Result = Value1 & Value2

PRINT bin Result ' Display AND result (%00001101)

or

PRINT bin (

%00001111 & %10101101

) ' Display

AND result (%00001101)

4.10. Or ‘|’

The OR operator (|) returns the

bitwise OR of two values. Each bit of the values is subject to the following

logic: -

0 OR 0 = 0

0 OR 1 = 1

1 OR 0 = 1

1 OR 1 = 1

The result returned by | will

contain 1s in any bit positions in which one

or the other (or both) input values

contain 1s: -

DIM Value1 as BYTE

DIM Value2 as BYTE

DIM Result as BYTE

Value1 = %00001111

Value2 = %10101001

Result = Value1 | Value2

PRINT bin Result ' Display OR result (%10101111)

or

PRINT bin ( %00001111 | %10101001 ) ' Display OR

result (%10101111)

4.11. Xor ‘^’

The Xor operator (^) returns the

bitwise XOR of two values. Each bit of the values is subject to the following

logic: -

0 XOR 0 = 0

0 XOR 1 = 1

1 XOR 0 = 1

1 XOR 1 = 0

The result returned by ^ will

contain 1s in any bit positions in which one or the other (but not both) input

values contain 1s: -

DIM Value1 as BYTE

DIM Value2 as BYTE

DIM Result as BYTE

Value1 = %00001111

Value2 = %10101001

Result = Value1 ^ Value2

PRINT bin Result ' Display XOR result (%10100110)

-- or --

PRINT bin ( %00001111 ^ %10101001 ) ' Display XOR result (%10100110)

-----------------------------------------------------------------------------------------------------------------

5 - PICBASIC

PLUS LITE Commands and Directives

ADIN Read on-chip analog to digital converter.

ASM-ENDASM Insert

assembly language code section.

BRANCH Computed GOTO (equiv. to ON..GOTO).

BRANCHL BRANCH out of page (long BRANCH).

BUSIN Read bytes from I2C device.

BUSOUT Write bytes to I2C device.

CALL Call assembly language subroutine.

CDATA Define initial contents in memory.

CLS Clear the LCD.

CONFIG Set or Reset

programming fuse configurations.

COUNTER Count

number of pulses on a pin.

CREAD Read word from code memory.

CURSOR Position the cursor on

the LCD.

CWRITE Write word to code memory.

DATA Define initial contents in memory.

DECLARE Adjust library routine

parameters.

DELAYMS Delay

(1mSec resolution).

DELAYUS Delay

(1uSec resolution).

DEVICE Choose the type of

PIC to compile with.

DIG Return the value of a decimal digit.

DIM Create a

variable.

EDATA Define initial contents of on-chip EEPROM.

END Stop execution.

EREAD Read byte or word from on-chip EEPROM.

EWRITE Write byte to on-chip EEPROM.

FOR…TO…NEXT…STEP Repeatedly execute statements.

GOSUB….RETURN Call BASIC subroutine at specified label.

GOTO Continue execution at specified label.

HIGH (or SET) Make pin, port, or register high.

IF…THEN…ELSE…ENDIF

Conditionally

execute statements.

INCLUDE Load a BASIC file into

the source code.

INKEY Scan a keypad.

INPUT Make pin an input.

[LET] Assign result of an expression to a variable.

LCDREAD Read

a single byte from a Graphic LCD. NOT

AVAILABLE IN LITE VERSION.

LCDWRITE Write

bytes to a Graphic LCD. NOT AVAILABLE IN LITE VERSION

LOOKDOWN Search

constant table for value.

LOOKDOWNL Search

constant / variable table for value.

LOOKUP Fetch constant value from table.

LOOKUPL Fetch

constant / variable value from table.

LOW (or CLEAR) Make pin, port, or register low.

ON_INTERRUPT Execute

a subroutine on a HARWARE interrupt.

OUTPUT Make

pin an output.

ORG Set

Program Origin.

PEEK Read byte from register.

PIXEL Read

a single pixel from a Graphic LCD. NOT AVAILABLE IN LITE VERSION

PLOT Set

a single pixel on a Graphic LCD. NOT AVAILABLE IN LITE VERSION

POKE Write byte to register.

POT Read potentiometer on specified pin.

PRINT Display characters on LCD.

PULSIN Measure pulse width on a pin.

PULSOUT Generate

pulse to a pin.

PWM Output pulse width modulated pulse train to pin.

RANDOM Generate a pseudo-random number.

RCIN Measure pulse width on a pin.

READ Read byte or word from memory.

REM Add a remark

to the source code.

REPEAT…UNTIL Execute statements until condition is true.

RESTORE Adjust the position of

data to READ.

RETURN Continue at statement following last GOSUB.

RSIN Asynchronous serial input from fixed pin and baud.

RSOUT Asynchronous serial output to fixed pin and baud.

SERVO Control a servo

motor.

SET_OSCCAL Calibrate the on-chip

oscillator.

SHIN Synchronous serial input.

SHOUT Synchronous serial output.

SNOOZE Power down processor for short period of time.

SLEEP Power down processor for a period of time.

SOUND Generate tone or white-noise on specified pin.

STOP Stop program execution.

SWAP Exchange the values of two variables.

SYMBOL Create an alias to a

constant, port, pin, or register

UNPLOT Clear

a single pixel on a Graphic LCD. NOT AVAILABLE IN LITE VERSION

WHILE…WEND Execute statements while condition is true.

-----------------------------------------------------------------------------------------------------------------

5.1. ADIN

Syntax : variable =

ADIN channel number

Overview : Read

the value from the on-board Analogue to Digital Converter.

Operators : Variable

is a user defined variable.

Channel number

can be a constant or a variable expression.

Example : ‘Read the value from channel 0 of the ADC and place in variable

Var.

DECLARE ADIN_RES 10 ‘ 10-bit result required

DECLARE ADIN_TAD FRC ‘ RC Osc chosen

DECLARE ADIN_STIME 50 ‘ Allow 50us sample time

DIM Var

as WORD

TRISA =

%00000001 ‘ Configure AN0 (PortA.0) as an input

ADCON1=%10000000 ‘ Set analogue input on PortA.0

Var=ADIN 0 ‘ Place the conversion into variable VAR

Declares : There

are three DECLARE directives for use with ADIN.

These are: -

DECLARE ADIN_RES 8 , 10 , or 12.

Sets the number of bits in the result.

If this DECLARE is not used, then the default is

the resolution of the PIC type used. For example, the new 16F87X range will

result in a resolution of 10-bits, while the standard PIC types will produce an

8-bit result. Using the above DECLARE allows an 8-bit result to be obtained

from the 10-bit PIC types, but NOT 10-bits from the 8-bit types.

DECLARE ADIN_TAD 2_FOSC , 8_FOSC , 32_FOSC , or FRC.

Sets the ADC’s clock source.

All compatible PICs have four options for the clock

source used by the ADC. 2_FOSC, 8_FOSC, and 32_FOSC, are ratios of the external

oscillator, while FRC is the PIC’s internal RC oscillator. Instead of using the

predefined names for the clock source, values from 0 to 3 may be used. These

reflect the settings of bits 0-1 in register ADCON0.

Care must be

used when issuing this DECLARE, as the wrong type of clock source may result in

poor resolution, or no conversion at all. If in doubt use FRC which will

produce a slight reduction in resolution and conversion speed, but is

guaranteed to work first time, every time. FRC is the default setting if the

DECLARE is not issued in the BASIC listing.

DECLARE ADIN_STIME 0 to 65535 microseconds (us).

Allows the internal capacitors to fully charge

before a sample is taken. This may be a value from 0 to 65535 microseconds

(us).

A value too small may result in a reduction of

resolution. While too large a value will result in poor conversion speeds

without any extra resolution being attained.

A typical value for ADIN_STIME is 50 to 100.

This allows adequate charge time without loosing too much conversion speed. But

experimentation will produce the right value for your particular requirement.

The default value if the DECLARE is not used in the BASIC listing is 50.

Notes

: Before the ADIN

command may be used, the appropriate TRIS register must be manipulated

to set the desired pin to an input. Also, the ADCON1 register must be

set according to which pin is required as an analogue input, and in some cases,

to configure the format of the conversion’s result. See the numerous Microchip

datasheets for more information on these registers and how to set them up

correctly for the specific device used.

If multiple conversions are being implemented, then a small delay should be used after the ADIN command. This allows the ADC’s internal capacitors to discharge fully: -

Again: Var = ADIN 3 ‘ Place the conversion into variable Var

DELAYUS 1 ‘ Wait for 1us

GOTO Again ‘ Read the ADC forever

See also : RCIN, POT

-----------------------------------------------------------------------------------------------------------------

5.2. ASM – ENDASM and @

Syntax : ASM

assembler mnemonics

ENDASM

or

@ assembler mnemonic

Overview

: Incorporate

in-line assembler in the BASIC code. The mnemonics are passed directly to the

assembler without the compiler interfering in any way. This allows a great deal

of flexibility that cannot always be achieved using BASIC commands alone.

The PICBASIC PLUS

compiler caters for using assembler like no other BASIC compiler

available. Because this is a rather detailed subject, section 6 has been

specially written to answer some of your questions and illustrate how assembler

mnemonics may be used with the compiler.

-----------------------------------------------------------------------------------------------------------------

5.3. BRANCH

Syntax : BRANCH Index,

[Label1 {,...Labeln }]

Overview

: Cause

the program to jump to different locations based on a variable index. On a PIC

device with only one page of memory.

Operators : Index is a constant,

variable, or expression, that specifies the address to branch to.

Label1,...Labeln

are valid labels that specify where to branch to.

Example

: DEVICE 16F84

DIM index as BYTE

Start: index

= 2 ‘assign index a value of 2

‘jump to label 2 (Lab_2) because index =

2

BRANCH index,[Lab_0, Lab_1,

Lab_2]

Lab_0: index

= 2 ‘index now equals 2

GOTO Start

Lab_1: index

= 0 ‘index now equals 0

GOTO Start

Lab_2: index

= 1 ‘index now equals 1

GOTO Start

The above example we first assign the index

variable a value of 2, then we define our labels. Since the first position is

considered 0 and the variable index equals 2 the BRANCH command will

cause the program to jump to the third label in the brackets [Lab2].

Notes : BRANCH is similar to the ON x GOTO

command found in other BASICs. It’s useful when you want to organise a

structure such as: -

IF Var = 0 THEN GOTO Lab_0 ' Var =0: go to label

"Lab_0"

IF Var = 1 THEN GOTO Lab_1 ' Var =1: go to label

"Lab_1"

IF Var = 2 THEN GOTO Lab_2 ' Var =2: go to label

"Lab_2"

You can use BRANCH to organize

this into a single statement: -

BRANCH Var, [Lab_0 , Lab_1, Lab_2]

This works exactly the same as the

above IF...THEN example. If the value is not in range (in this

case if Var is greater than 2), BRANCH does nothing. The program continues

with the next instruction..

The BRANCH command is primarily for use with

PIC devices that have one page of memory (0-2047). If larger PIC’s are used and

you suspect that the branch label will be over a page boundary, use the BRANCHL

command instead.

See

also : BRANCHL

-----------------------------------------------------------------------------------------------------------------

5.4. BRANCHL

Syntax : BRANCHL Index,

[Label1 {,...Labeln }]

Overview

: Cause

the program to jump to different locations based on a variable index. On a PIC

device with more than one page of memory.

Operators

: Index is a

constant, variable, or expression, that specifies the address to branch to.

Label1,...Labeln

are valid labels that specify where to branch to.

Example

: DEVICE 16F877

DIM index as BYTE

Start: index

= 2 ‘assigned index a value of 2

‘jump to label 2 (Lab2) because index =

2

BRANCHL index , [Lab0, Lab1,

Lab2]

Lab1: index

= 2 ‘index now equals 2

GOTO Start

Lab2: index

= 0 ‘index now equals 0

GOTO Start

Lab3: index

= 1 ‘index now equals 1

GOTO Start

The above example we first assign the index

variable a value of 2, then we define our labels. Since the first position is

considered 0 and the variable index equals 2 the BRANCHL command will

cause the program to jump to the third label in the brackets [Lab2].

Notes

: The BRANCHL

command is mainly for use with PIC devices that have more than one page of

memory (greater than 2048). It may also be used on any PIC device, but does

produce code that is larger than BRANCH.

See

also : BRANCH

-----------------------------------------------------------------------------------------------------------------

5.5. BUSIN

Syntax : Variable = BUSIN Control

, { Address }

or

BUSIN Control

, { Address }, [ Variable {, Variable…} ]

Overview

: Receives

a value from the I2C bus and places it into variable/s. By

first sending the control and optional address out of the clock

pin (SCL), and data pin (SDA).

Operators : Variable is

a user defined variable or constant.

Control

may be a constant value or a BYTE sized variable expression.

Address

may be a constant value or a variable expression.

The two variations of the BUSIN command may

both be used in the same BASIC program. The first type is useful for simply

receiving a single value from the bus. The second type may be used to receive

several values and designate each to a separate variable.

The BUSIN command operates as an I2C

master and may be used to interface with any device that complies with the 2-wire

I2C protocol.

The most significant 7-bits of control byte

contain the control code and the slave address of the device being interfaced

with. Bit-0 is the flag that indicates whether a read or write command is being

implemented.

For example, if we were interfacing to an external

eeprom such as the 24C32, the control code would be %10100001 or $A1. The most

significant 4-bits (1010) are the eeprom’s unique slave address. Bits 2 to 3

reflect the three address pins of the eeprom. And Bit-0 is set to signify that

we wish to read from the eeprom. Note that this bit is automatically set by the

BUSIN command, regardless of its initial setting.

Example : ‘ Receive a byte from the I2C bus and place it into

variable Var.

DIM Var

as BYTE ‘ We’ll

only read 8-bits

DIM Address

as WORD ‘ 16-bit address

required

SYMBOL Control

%10100001 ‘ Target an eeprom

Address = 20 ‘ Read the value at address 20

Var = BUSIN Control

, Address ‘

Read the byte from the eeprom

or

BUSIN Control

, Address, [ Var ] ‘ Read the byte from the eeprom

Address, is an optional

parameter that may be an 8-bit or 16-bit value. If a variable is used in this

position, the size of address is dictated by the size of the variable

used (BYTE or WORD). In the case of the previous eeprom interfacing, the 24C32

eeprom requires a 16-bit address. While the smaller types require an 8-bit

address. Make sure you assign the right size address for the device interfaced

with, or you may not achieve the results you intended.

The value received from the bus depends on the size

of the variables used. For example: -

DIM Wrd as WORD ‘ Declare a WORD size variable

Wrd = BUSIN Control , Address

Will receive a 16-bit value from the bus. While: -

DIM Var as BYTE ‘ Declare a BYTE size variable

Var = BUSIN Control , Address

Will receive an 8-bit value from the bus.

Using the second variation of the BUSIN

command allows differing variable assignments. For example: -

DIM

Var as BYTE

DIM

Wrd as WORD

BUSIN

Control , Address , [ Var , Wrd ]

Will receive two values from the bus, the first

being an 8-bit value dictated by the size of variable VAR which has been

declared as a byte. And a 16-bit value, this time dictated by the size of the

variable WRD which has been declared as a word. Of course, BIT type variables

may also be used, but in most cases these are not of any practical use as they

still take up a byte within the eeprom.

Declares : There

are three DECLARE directives for use with BUSIN.

These are: -

DECLARE SDA_PIN

PORT . PIN

Declares the

port and pin used for the data line (SDA). This may be any valid port on the

PIC. If this declare is not issued in the BASIC program, then the default Port

and Pin is PortA.0

DECLARE SCL_PIN

PORT . PIN

Declares the

port and pin used for the clock line (SCL). This may be any valid port on the

PIC. If this declare is not issued in the BASIC program, then the default Port

and Pin is PortA.1

These declares, as

is the case with all the DECLARES, may only be issued once in any single

program, as they setup the I2C library code at design time.

You may imagine that it’s limiting having a fixed

interface, but you must remember that several different devices may be attached

to a single bus, each having a unique slave address. Which means there is no

need to use up more than two pins on the PIC.

DECLARE SLOW_BUS ON - OFF

or 1 - 0

Slows the bus speed when using an oscillator higher

than 4MHz.

The standard speed for the I2C bus is

100KHz. Some devices use a higher bus speed of 400KHz. If you use an 8MHz or

higher oscillator, the bus speed may exceed the devices specs, which will

result in intermittent reads, or in some cases, no reads at all. Therefore, use

this DECLARE if you are not sure of the device’s spec. The datasheet for the device

used will inform you of its bus speed.

Notes : When the BUSIN command is used, the appropriate SDA and SCL Port and Pin are automatically setup for ins and outs.

Because the I2C protocol calls for an open-collector

interface, pull-up resistors are required on both the SDA and SCL lines. Values

of 4.7K to 10K Ohms will suffice.

See also : BUSOUT for suitable circuit, DECLARE

-----------------------------------------------------------------------------------------------------------------

5.6. BUSOUT

Syntax : BUSOUT Control

, { Address } , [ Variable {, Variable…} ]

Overview

: Transmit

a value to the I2C bus by first sending the control and

optional address out of the clock pin (SCL), and data pin (SDA).

Operators : Variable is

a user defined variable or constant.

Control

may be a constant value or a BYTE sized variable expression.

Address

may be a constant, variable, or expression.

The BUSOUT command operates as an I2C

master and may be used to interface with any device that complies with the

2-wire I2C protocol.

The most significant 7-bits of control byte

contain the control code and the slave address of the device being interfaced

with. Bit-0 is the flag that indicates whether a read or write command is being

implemented.

For example, if we were interfacing to an external

eeprom such as the 24C32, the control code would be %10100000 or $A0. The most

significant 4-bits (1010) are the eeprom’s unique slave address. Bits 2 to 3

reflect the three address pins of the eeprom. And Bit-0 is clear to signify

that we wish to write to the eeprom. Note that this bit is automatically

cleared by the BUSOUT command, regardless of its initial value.

Example : ‘ Send a byte to the I2C bus.

DIM Var

as BYTE ‘ We’ll

only read 8-bits

DIM Address

as WORD ‘ 16-bit address

required

SYMBOL Control

%10100000 ‘ Target an eeprom

Address = 20 ‘ Write to address 20

Var = 200 ‘ The value place into address 20

BUSOUT Control

, Address , [ Var ] ‘ Send the byte to the eeprom

DELAYMS 5 ‘ Allow time for allocation of byte

Address, is an optional

parameter that may be an 8-bit or 16-bit value. If a variable is used in this

position, the size of address is dictated by the size of the variable

used (BYTE or WORD). In the case of the above eeprom interfacing, the 24C32

eeprom requires a 16-bit address. While the smaller types require an 8-bit

address. Make sure you assign the right size address for the device interfaced

with, or you may not achieve the results you intended.

The value sent to the bus depends on the size of

the variables used. For example: -

DIM Wrd as WORD ‘ Declare a WORD size variable

BUSOUT Control , Address

, [ Wrd ]

Will send a 16-bit value to the bus. While: -

DIM Var as BYTE ‘ Declare a BYTE size variable

BUSOUT Control , Address

, [ Var ]

Will send an 8-bit value to the bus.

Using more than one variable within the brackets

allows differing variable sizes to be sent. For example: -

DIM

Var as BYTE

DIM

Wrd as WORD

BUSOUT

Control , Address , [ Var , Wrd ]

Will send two values to the bus, the first being an

8-bit value dictated by the size of variable VAR which has been declared as a

byte. And a 16-bit value, this time dictated by the size of the variable WRD

which has been declared as a word. Of course, BIT type variables may also be

used, but in most cases these are not of any practical use as they still take

up a byte within the eeprom.

A string of characters can also be transmitted, by

enclosing them in quotes: -

BUSOUT Control , Address

, [ “Hello World” , Var , Wrd ]

Declares : There

are four DECLARE directives for use with BUSOUT.

These are: -

DECLARE SDA_PIN

PORT . PIN

Assigns the port

and pin used for the data line (SDA). This may be any valid port on the PIC. If

this declare is not issued in the BASIC program, then the default Port and Pin

is PortA.0

DECLARE SCL_PIN

PORT . PIN

Assigns the port

and pin used for the clock line (SCL). This may be any valid port on the PIC.

If this declare is not issued in the BASIC program, then the default Port and

Pin is PortA.1

These declares,

as is the case with all the DECLARES, may only be issued once in any single

program, as they setup the I2C library code at design time.

You may imagine

that it’s limiting having a fixed interface, but you must remember that several

different devices may be attached to a single bus, each having a unique slave

address.

Which means there is no need to use up more

than two pins on the PIC.

DECLARE SLOW_BUS ON - OFF

or 1 - 0.

Slows the bus speed when using an oscillator higher

than 4MHz.

The standard speed for the I2C bus is

100KHz. However, some devices use a higher bus speed of 400KHz. If you use an

8MHz or higher oscillator, the bus speed may exceed the devices specs, which

will result in intermittent writes, or in some cases, no writes at all.

Therefore, use this DECLARE if you are not sure of the device’s spec. The

datasheet for the device used will inform you of its bus speed.

Notes : When the BUSOUT command is used, the appropriate SDA and SCL Port and Pin are automatically setup for ins and outs.

Because the I2C

protocol calls for an open-collector interface, pull-up resistors are

required on both the SDA and SCL lines. Values from 4.7KW to 10KW

will usually suffice.

See also : BUSIN

|

|

|

|

A typical use for the I2C commands is for interfacing with serial eeproms. The diagram shows the connections to the I2C bus of a 24C32 serial eeprom.

-----------------------------------------------------------------------------------------------------------------

5.7. CALL

Syntax : CALL

Label

Overview

: Execute

the assembly language subroutine named label.

Operators

: Label must

be a valid label name.

Example

: ‘ Call an assembler routine

CALL

Asm_Sub

ASM

Asm_Sub

{mnemonics}

Return

ENDASM

Notes

: The

GOSUB command is usually used to execute a BASIC subroutine. However, if

your subroutine happens to be written in assembler, the CALL command

should be used. The main difference between GOSUB and CALL is

that when CALL is used, the label’s existence is not checked

until assembly time. Using CALL, a label in an assembly language

section can be accessed that would otherwise be inaccessible to GOSUB.

This also means that any errors produced will be assembler types.

See also : GOSUB,

GOTO

-----------------------------------------------------------------------------------------------------------------

5.8. CDATA

Syntax : CDATA

{ alphanumeric data }

Overview

: Place

information directly into memory for access by CREAD and CWRITE.

Operators : alphanumeric data can be any alphabetic character or string enclosed in quotes (“) or numeric data without quotes.

Example : DEVICE

16F877 ‘ Use a

16F877 PIC

DIM

Var as BYTE

Var

= CREAD 2000 ‘ Read the

data from address 2000

ORG

2000 ‘ Set the address of the CDATA command

CDATA

120 ‘ Place 120 at address 2000

In

the above example, the data is located at address 2000 within the PIC, then

it’s read using the CREAD command.

Notes : CDATA is only available on the

newer PIC types that have self-modifying features, such as the 16F87x range.

In

order for the CREAD and CWRITE commands to locate the data in

memory, CDATA commands should be preceded by an ORG directive.

ORG

4000 ‘

Move the address pointer to 4000

CDATA

“Hello World” , 16200

, 253 ‘ Place the data at address 4000

The

above example, places the data “Hello World” at address 4000 within the PIC.

You must make sure that this area is not being used by your program. This can

be done by examining the last address in the HEX window.

An

alternative, and I think better, method for locating the address of the CDATA

table is by using a small ASM routine: -

DIM

Lab_Addr as WORD

' Get the address of CDATA LABEL into

variable Lab_Addr

@ Movlw High

Table ; Get hi address of table

Wreg_Byte Lab_AddrH ; Place into Variable

@ Movlw Low

Table ; Get lo address of table

Wreg_Byte Lab_Addr ; Place into Variable

{ rest of code }

Table:- CDATA { list of values }

By placing the above code at the

top of a program, the CDATA’s address is now held in the variable

LAB_ADDR.

This may

now be used in any expression, or more importantly, in the CWRITE and CREAD

commands. It also allows the CDATA table to be located anywhere in

memory without the use of the ORG directive.

Notice

the dash after the label’s name, this

disables any bank switching code that may otherwise disturb the location in

memory of the CDATA table. Also the use of the pseudo command WREG_BYTE,

this is explained in the ‘using assembler section’ of the manual.

The

configuration fuse setting WRTE must be enabled before CDATA, CREAD,

and CWRITE may be used. This enables the self-modifying feature. If the CONFIG

directive is used, then the WRTE_ON fuse setting must be included in the list:

-

CONFIG

WDT_ON , XT_OSC

, WRTE_ON

Because the 14-bit core devices are only capable of

holding 14 bits to a WORD, values greater than 16383 ($3FFF) cannot be stored.

See also : CONFIG,

CREAD, CWRITE, ORG

-----------------------------------------------------------------------------------------------------------------

5.9. CLS

Syntax : CLS

Overview

: Clears

the alphanumeric or graphic LCD and places the cursor at the home position i.e.

line 1, position 1

Example : CLS ‘ Clear the LCD

PRINT "HELLO" ‘ Display the word “HELLO” on the LCD

CURSOR 2 ,

1 ‘ Move the cursor to line 2, position 1

PRINT "WORLD" ‘

Display the word “WORLD” on the LCD

In the above example, the LCD is cleared using the CLS

command, which also places the cursor at the home position i.e. line 1,

position 1. Next, the word HELLO is displayed in the top left corner. The

cursor is then moved to line 2 position 1, and the word WORLD is displayed.

See also : CURSOR, DECLARE, see PRINT for an

LCD connection circuit.

-----------------------------------------------------------------------------------------------------------------

5.10. CONFIG

Syntax : CONFIG {

configuration fuse settings }

Overview

: Enable

or Disable particular fuse settings for the PIC type used.

Operators

: configuration fuse settings vary

from PIC to PIC, however, certain settings are standard to all PIC types. These

are: -

WDT_ON

Enable the internal Watchdog timer.

WDT_OFF

Disable the internal Watchdog timer.

HS_OSC

Use a High-speed crystal (Xtals over 4MHz) .

XT_OSC

Use a standard crystal (4MHz or under).

LP_OSC

Use a low frequency crystal (KHz range).

PWRTE_ON

Enable power up timer.

PWRTE_OFF

Disable power up timer.

Example : ‘ Disable the Watchdog timer and specify an HS_OSC

CONFIG WDT_OFF , HS_OSC

Notes

: If the CONFIG

directive is not used within the BASIC program then default values are used.

These may be found in the .LPB files in the INC folder.

Any fuse names

that are omitted from the CONFIG list will normally assume an OFF or

DISABLED state. However, this also applies to the OSC settings, therefore, if

no OSC fuse is indicated, then the default will be LP_OSC.

Before

programming the PIC, always check the fuse settings in the programmer window.

Always read the

datasheet for the particular PIC of interest, before using this directive.

-----------------------------------------------------------------------------------------------------------------

5.11. COUNTER

Syntax : Variable

= COUNTER Pin

, Period

Overview

: Count

the number of pulses that appear on pin during period, and store

the result in variable.

Operators : Variable is

a user-defined variable.

Pin

is a Port.Pin constant declaration i.e. PortA.0.

Period

may be a constant, variable, or expression.

Example : ‘ Count the pulses that occur on PortA.0 within a 100ms period

‘ and displays

the results.

DIM Wrd

as WORD ‘ Declare a word size variable

SYMBOL Pin

= PortA.0 ‘ Assign the input pin to PortA.0

CLS

Loop: Wrd=COUNTER

, Pin , 100 ‘ Variable

Wrd now contains the Count

CURSOR 1 , 1

PRINT dec

Wrd , “ “ ‘ Display

the decimal result on the LCD

GOTO Loop ‘ Do it indefinitely

Notes

: The

resolution of period is in milliseconds (ms). It obtains its scaling from the

oscillator declaration, DECLARE XTAL.

COUNTER checks the state

of the pin in a concise loop, and counts the rising edge of a transition (low

to high).

With a 4MHz oscillator, the pin is checked every

20us, and every 4us with a 20MHz oscillator. From this we can determine that

the highest frequency of pulses that may be counted is: -

25KHz using a 4MHz oscillator.

125KHz using a 20MHz oscillator.

See also : DECLARE

-----------------------------------------------------------------------------------------------------------------

5.12. CREAD

Syntax : Variable = CREAD Address

Overview

: Read

data from anywhere in memory.

Operators : Variable is

a user-defined variable.

Address is

a constant, variable, or expression, that represents any valid address within

the PIC.

Example : ‘ Read memory locations within

the PIC

DEVICE 16F877 ‘ Needs to be a 16F87x type PIC

DIM

Var as BYTE

DIM

Wrd as WORD

DIM

Address as WORD

Address=1000

‘ Address now holds the base address

Var

= CREAD 1000 ‘ Read 8-bit

data at address 1000 into Var

Wrd

= CREAD Address+10 ‘ Read

14-bit data at address 1000+10

Notes

: The CREAD

command takes advantage of the new self-modifying feature that is available in

the newer 16F87x range of devices.

If a WORD size

variable is used as the assignment, then a 14-bit WORD will be read. If a BYTE

sized variable is used as the assignment, then 8-bits will be read.

Because the

14-bit core devices are only capable of holding 14 bits to a WORD, values

greater than 16383 ($3FFF) cannot be read.

See CDATA

for an alternative method for locating the address of a CDATA table.

The

configuration fuse setting WRTE must be enabled before CDATA, CREAD,

and CWRITE may be used, this is the default setting. This enables the

self-modifying feature. If the CONFIG directive is used, then the

WRTE_ON fuse setting must be included in the list: -

CONFIG

WDT_ON , XT_OSC

, WRTE_ON

See

also : CDATA, CONFIG, CWRITE,

ORG

-----------------------------------------------------------------------------------------------------------------

5.13. CURSOR

Syntax : CURSOR

Line , Position

Overview : Move

the cursor position on the LCD to a specified line and position.

Operators

: Line is

a constant, variable, or expression that corresponds to the line number from 1

to maximum lines.

Position is

a constant, variable, or expression that moves the position within the line

chosen, from 1 to maximum position.

Example 1 : DIM

Line as BYTE

DIM

Xpos as BYTE

Line = 2

Xpos = 1

CLS ‘ Clear the LCD

PRINT "HELLO" ‘ Display the word “HELLO” on the LCD

CURSOR Line , Xpos ‘ Move the

cursor to line 2, position 1

PRINT "WORLD" ‘ Display the word “WORLD” on the LCD

In

the above example, the LCD is cleared using the CLS command, which also

places the cursor at the home position i.e. line 1, position 1. Next, the word

HELLO is displayed in the top left corner. The cursor is then moved to line 2

position 1, and the word WORLD is displayed.

Example

2 : DIM Xpos as BYTE

DIM Ypos as BYTE

Again: Ypos = 1 ‘ Start on line 1

FOR Xpos = 1 TO 16 ‘ Create a loop of

16

CLS ‘ Clear the LCD

CURSOR Ypos , Xpos ‘ Move the cursor

to position Ypos,Xpos

PRINT "*" ‘ Display the

character

DELAYMS 100

NEXT

Ypos = 2 ‘ Move to line 2

FOR Xpos = 16 TO 1 STEP -1 ‘ Create another

loop, this time reverse

CLS ‘ Clear the LCD

CUSROS Ypos , Xpos ‘ Move the cursor

to position Ypos,Xpos

PRINT "*" ‘ Display the

character

DELAYMS 100

NEXT

GOTO Again ‘ Repeat forever

Example 2

displays an asterisk character moving around the perimeter of a 2-line by 16

character LCD.

See also : CLS, see PRINT for an LCD

connection circuit

-----------------------------------------------------------------------------------------------------------------

5.14. CWRITE

Syntax : CWRITE Address

, [ Variable { , Variable…} ]

Overview

: Write

data to anywhere in memory.

Operators : Variable can

be a constant, variable, or expression.

Address is

a constant, variable, or expression that represents any valid address within

the PIC.

Example : ‘ Write to memory location

2000+ within the PIC

DEVICE 16F877 ‘ Needs to be a 16F87x type PIC

DIM

Var as BYTE

DIM

Wrd as WORD

DIM

Address as WORD

Address

= 2000 ‘ Address now holds the base address

Var

= 234

Wrd

= 1043

CWRITE

Address, [10, Var, Wrd ] ‘ Write to address 2000 +

ORG

2000

Notes

: The CWRITE

command takes advantage of the new self-modifying feature that is available in

the newer 16F87x range of devices.

If a WORD size

variable is used, then a 14-bit WORD will be written. If a BYTE sized variable

is used, then 8-bits will be written.

Because the

14-bit core devices are only capable of holding 14 bits to a WORD, values

greater than 16383 ($3FFF) cannot be written.

See CDATA

for an alternative method for locating the address of a CDATA table.

The

configuration fuse setting WRTE must be enabled before CDATA, CREAD,

and CWRITE may be used. This enables the self-modifying feature. If the CONFIG

directive is used, then the WRTE_ON fuse setting must be included in the list:

-

CONFIG

WDT_ON , XT_OSC

, WRTE_ON, LVPE_OFF

Take

care not to overwrite existing code when using the CWRITE commands, and

also remember that the all PICmicro devices have a finite amount of write

cycles (approx 1000). A single program can easily exceed this limit, making

that particular memory cell or cells inaccessible.

See also : CDATA, CONFIG, CREAD, ORG

-----------------------------------------------------------------------------------------------------------------

5.15. DATA

Syntax : DATA { alphanumeric

data }

Overview : Defines a table of alphanumeric data.

Operators : alphanumeric data can be any alphabetic character or string enclosed in quotes (“) or numeric data without quotes.

Example : DIM Var as BYTE

DATA 5 , 8 , ”fred” , 12

RESTORE

READ Var ‘ Variable Var will now contain the value 5

READ Var ‘ Variable Var will now contain the value 8

‘

Pointer now placed at location 4 in our data table i.e. “r”

RESTORE 3

‘ Var

will now contain the value 114 i.e. the ‘r’ character in decimal

READ Var

The data table is defined with the values 5,8,102,114,101,100,12 as “fred” equates to f:102, r:114, e:101, d:100 in decimal. The table pointer is immediately restored to the beginning of the table. This is not always required but as a general rule, it is a good idea to prevent table reading from overflowing.

The first READ Var, takes the first item of data from the table and increments the table pointer. The next READ Var therefore takes the second item of data. RESTORE 3 moves the table pointer to the fourth location (first location is pointer position 0) in the table - in this case where the letter ‘r’ is. READ Var now retrieves the decimal equivalent of ‘r’ which is 114.

Notes : DATA tables should be placed near the beginning of your program. Attempts to read past the end of the table will result in errors and unpredictable results.

Only one instance of DATA is allowed per program, however, they be of any length. If the alphanumeric contents of the DATA statement will not fit on one line then the extra information must be placed directly below using another DATA statement: -

DATA “HELLO ”

DATA “WORLD”

is the same as: -

DATA “HELLO WORLD”

See also: READ , RESTORE

-----------------------------------------------------------------------------------------------------------------

5.16. DECLARE

Syntax : DECLARE

code modifying directive , modifying value

Overview

: Adjust certain aspects

of the produced code, i.e. Crystal frequency, LCD port and pins, serial baud

rate etc.

Operators

: code modifying

directive is a set of pre-defined words. See list

below.

modifying value

is the value that corresponds to the command. See list below.

ADIN Declares.

DECLARE ADIN_RES

8 , 10 ,

or 12.

Sets the number of bits in the result.

If this DECLARE is not used, then the default is

the resolution of the PIC type used. For example, the new 16F87X range will

result in a resolution of 10-bits, while the standard PIC types will produce an

8-bit result. Using the above DECLARE allows an 8-bit result to be obtained

from the 10-bit PIC types, but NOT 10-bits from the 8-bit types.

DECLARE ADIN_TAD

2_FOSC , 8_FOSC

, 32_FOSC , or FRC.

Sets the ADC’s clock source.

All compatible PICs have four options for the clock

source used by the ADC, 2_FOSC, 8_FOSC, and 32_FOSC,

are ratios of the external oscillator, while FRC

is the PIC’s internal RC oscillator. Instead of using the predefined names for

the clock source, values from 0 to 3 may be used. These reflect the settings of

bits 0-1 in register ADCON0.

Care must be

used when issuing this DECLARE, as the wrong type of clock source may result in

poor resolution, or no conversion at all. If in doubt use FRC which will

produce a slight reduction in resolution and conversion speed, but is

guaranteed to work first time, every time. FRC is the default setting if the

DECLARE is not issued in the BASIC listing.

DECLARE

ADIN_STIME 0 to 65535 microseconds (us).

Allows the internal capacitors to fully charge

before a sample is taken. This may be a value from 0 to 65535 microseconds

(us).

A value too small may result in a reduction of

resolution. While too large a value will result in poor conversion speeds

without any extra resolution being attained.

A typical value for ADIN_STIME is 50 to 100.

This allows adequate charge time without loosing too much conversion

speed. But experimentation will produce

the right value for your particular requirement. The default value if the DECLARE

is not used in the BASIC listing is 50.

BUSIN, BUSOUT Declares.

DECLARE SDA_PIN PORT .

PIN

Declares the

port and pin used for the data line (SDA). This may be any valid port on the

PIC. If this declare is not issued in the BASIC program, then the default Port

and Pin is PortA.0

DECLARE SCL_PIN

PORT . PIN

Declares the

port and pin used for the clock line (SCL). This may be any valid port on the

PIC. If this declare is not issued in the BASIC program, then the default Port

and Pin is PortA.1

DECLARE SLOW_BUS ON - OFF

or 1 - 0

Slows the bus speed when using an oscillator higher

than 4MHz.

The standard speed for the I2C bus is

100KHz. However, some devices use a higher bus speed of 400KHz. If an 8MHz or

higher oscillator is used, the bus speed may exceed the device’s specs, which

will result in intermittent writes or reads, or in some cases, none at all.

Therefore, use this DECLARE if you are not sure of the device’s spec. The datasheet

for the device used will inform you of its bus speed.

LCD Declares.

DECLARE

LCD_DTPIN PORT . PIN

Assigns

the Port and Pins that the LCD’s DT lines will attach to.

The LCD may be connected to the PICmicro using

either a 4-bit bus or an 8-bit bus. If an 8-bit bus is used, all 8 bits must be

on one port. If a 4-bit bus is used, it must be connected to either the bottom

4 or top 4 bits of one port. For example: -

DECLARE LCD_DTPIN PORTB.4 ‘ Used for 4-line interface.

DECLARE LCD_DTPIN PORTB.0 ‘ Used for 8-line interface.

In the above examples, PortB is only a personal

preference. The LCD’s DT lines can be attached to any valid port on the PIC. If

the DECLARE is not used in the program, then the default Port and Pin is PortB.4,

which assumes a 4-line interface.

.

DECLARE

LCD_ENPIN PORT . PIN

Assigns the Port and Pin that the LCD’s EN line

will attach to. This also assigns the graphic LCD’s EN pin, however, the

default value remains the same as for the alphanumeric type, so this will

require changing.

If the DECLARE is not used in the program, then the

default Port and Pin is PortB.2.

DECLARE

LCD_RSPIN PORT . PIN

Assigns the Port and Pins that the LCD’s RS line

will attach to. This also assigns the graphic LCD’s RS pin, however, the

default value remains the same as for the alphanumeric type, so this will

require changing.

If the DECLARE is not used in the program, then the

default Port and Pin is PortB.3.

DECLARE

LCD_INTERFACE 4 or 8

Inform the compiler as to whether a 4-line or

8-line interface is required by the LCD.

If the DECLARE is not used in the program, then the

default interface is a 4-line type.

DECLARE

LCD_LINES 1 , 2 , or 4

Inform

the compiler as to how many lines the LCD has.

LCD’s come in a range of sizes, the most popular

being the 2 line by 16 character types. However, there are 4-line types as

well. Simply place the number of lines that the particular LCD has into the

declare.

If the DECLARE is not used in the program, then the

default number of lines is 2.

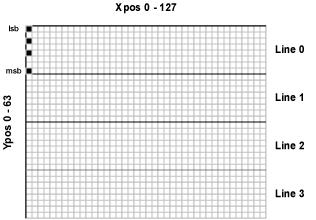

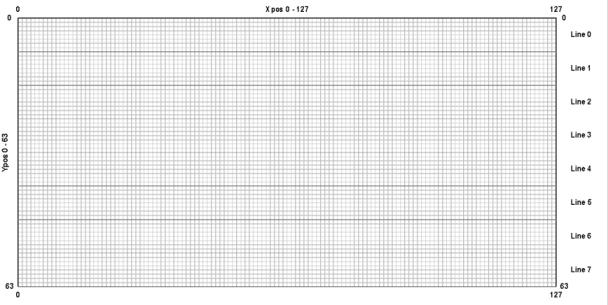

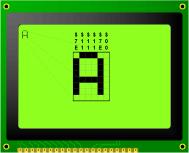

GRAPHIC LCD Declares. (NOT AVAILABLE IN THE LITE

VERSION)

DECLARE

LCD_TYPE 1

or 0 , GRAPHIC or ALPHA

Inform

the compiler as to the type of LCD that the PRINT command will output

to. If GRAPHIC or 1 is chosen then any output by the PRINT command will

be directed to a graphic LCD based on the Samsung S6B0108 chipset. A value of 0

or ALPHA, or if the DECLARE is not

issued

will target the standard alphanumeric LCD type

Targeting

the graphic LCD will also enable commands such as PLOT, UNPLOT, LCDGET,

and LCDPUT.

DECLARE LCD_DTPORT PORT

Assign the port that will output the

8-bit data to the graphic LCD.

If the DECLARE is not used, then the

default port is PORTB.

DECLARE LCD_RWPIN PORT . PIN

Assigns

the Port and Pin that the graphic LCD’s RW line will attach to.

If the DECLARE is not used in the program,

then the default Port and Pin is PortC.0.

DECLARE LCD_CS1PIN PORT . PIN

Assigns

the Port and Pin that the graphic LCD’s CS1 line will attach to.

If the DECLARE is not used in the program,

then the default Port and Pin is PortC.0.

DECLARE LCD_CS2PIN PORT . PIN

Assigns

the Port and Pin that the graphic LCD’s CS2 line will attach to.

If the DECLARE is not used in the program,

then the default Port and Pin is PortC.0.

DECLARE INTERNAL_FONT ON

- OFF, 1 or 0

The graphic LCD’s that are compatible with PICBASIC PLUS are

non-intelligent types, therefore, a separate character set is required. This

may be in one of two places, either externally, in an I2C eeprom, or

internally in a CDATA table.

If an external font is chosen, the I2C eeprom must be

connected to the specified SDA and SCL pins (as dictated by DECLARE SDA and

DECLARE SCL).

If an internal font is chosen, it must be on a PIC device that has self

modifying code features, such as the 16F87X range.

The CDATA table that contains the font must have a label, named

FONT: preceding it. For example: -

FONT: CDATA $7E , $11 , $11 , $11 , $7E , $0 ‘ Chr “A”

CDATA $7F , $49 , $49 , $49 , $36 , $0 ‘ Chr “B”

{ rest of font table }

The font table may be anywhere in memory, however, it is best placed

after the main program code.

If the DECLARE is omitted from the program, then an external font is

the default setting.

DECLARE FONT_ADDR 0 to 7

Set the slave address for the I2C

eeprom that contains the font.

When an external source for

the font is chosen, it may be on any one of 8 eeproms attached to the I2C

bus. So as not to interfere with any other eeproms attached, the slave address

of the eeprom carrying the font code may be chosen.

If the DECLARE is omitted

from the program, then address 0 is the default slave address of the font

eeprom.

KEYPAD Declare.

DECLARE

KEYPAD_PORT PORT

Assigns

the Port that the keypad is attached to.

The keypad routine requires pull-up resistors,

therefore, the best Port for this device is PortB which comes equipped with

internal pull-ups. If the DECLARE is not used in the program, then PortB is the

default Port.

RSIN-RSOUT Declares.

DECLARE

RSOUT_PIN PORT . PIN

Assigns the Port and Pin that will be used to

output serial data from the RSOUT command. This may be any valid port on

the PIC.

If the DECLARE is not used in the program, then the

default Port and Pin is PortB.0.

DECLARE

RSIN_PIN

PORT . PIN

Assigns the Port and Pin that will be used to input

serial data by the RSIN command. This may be any valid port on the PIC.

If the DECLARE is not used in the program, then the

default Port and Pin is PortB.1.

DECLARE

RSOUT_MODE INVERTED , TRUE or 1 , 0

Sets the serial mode for the data transmitted by RSOUT.

This may be inverted or true. Alternatively, a value of 1 may be substituted to

represent inverted, and 0 for true.

If the DECLARE is not used in the program, then the

default mode is INVERTED.

DECLARE RSIN_MODE INVERTED , TRUE

or 1 , 0

Sets the serial mode for the data received by RSIN.

This may be inverted or true. Alternatively, a value of 1 may be substituted to

represent inverted, and 0 for true.

If the DECLARE is not used in the program, then the

default mode is INVERTED.

DECLARE SERIAL_BAUD 0 to 65535 bps (baud)

Informs the RSIN and RSOUT routines

as to what baud rate to receive and transmit data.

Virtually any baud rate may be transmitted and

received, but there are standard bauds, namely: -

300, 600, 1200, 2400, 4800, 9600, and 19200.

When using a 4MHz crystal, the highest baud rate

that is reliably achievable is 9600. However, an increase in the oscillator

speed allows higher baud rates to be achieved, including 38400 baud.

If the DECLARE is not used in the program, then the

default baud is 9600.

DECLARE RSOUT_PACE 0 to 65535

microseconds (us)

Implements a delay between characters transmitted

by the RSOUT command.

On occasion, the characters transmitted serially

are in a stream that is too fast for the receiver to catch, this results in

missed characters. To alleviate this, a delay may be implemented between each

individual character transmitted by RSOUT.

If the DECLARE is not used in the program, then the

default is no delay between characters.

DECLARE RSIN_TIMEOUT

0 to 65535 microseconds (us)

Sets the time, in ms, that RSIN will wait

for a start bit to occur.

RSIN waits in a tight loop

for the presence of a start bit. If no timeout parameter is issued, then it

will wait forever.

The RSIN command has the option of jumping

out of the loop if no start bit is detected within the time allocated by timeout.

If

the DECLARE is not used in the program, then the default timeout value is 10000us or 10ms.

SHIN-SHOUT

Declare.

DECLARE

SHIFT_DELAYUS 0 - 65535

microseconds (us)

Extend

the active state of the shift clock.

The clock used by SHIN and SHOUT runs

at approximately 45KHz dependent on the oscillator. The active state is held

for a minimum of 2 microseconds. By placing this declare in the program, the

active state of the clock is extended by an additional number of microseconds

up to 65535 (65.535 milliseconds) to slow down the clock rate.

If the DECLARE is not used in the program, then the

default is no clock delay.

CRYSTAL Frequency Declare.

DECLARE XTAL 4 , 8

, 10 , 12 , 16 , or 20 (4MHz and 20MHz only in the LITE version)

Inform the

compiler as to what frequency crystal is being used.

Some commands are very dependant on the oscillator

frequency, RSIN, RSOUT, DELAYMS, and DELAYUS being

just a few. In order for the compiler to adjust the correct timing for these

commands, it must know what frequency crystal is being used.

If the DECLARE is not used in the program, then the

default frequency is 4MHz.

Notes

: The DECLARE